Electrostatic Spray Technology

By: Christopher Low

Picture from http://www.proaginc.com/

Introduction: Throughout the years, research has shown that pesticide drift causes damage to nontarget organisms. Sometimes drift from certain chemicals can be detected on succeptible plants and animals miles away. As farmers begin to realize the environmental impacts of some of the older practices in agriculture, they are demanding spray equipment that is more efficient and safer for the environment.

The first step in reducing spray drift is timing. The applicator must look at the temperature, humidity, and wind speed to see how these factors would affect the spread of the pesticide. Most agricultural chemicals are volatile at higher temperatures. After consulting the pesticide label, this must be taken into account. Higher humidity is good to reduce the chances of the small droplet evaporating and not hitting their target. Thirdly, wind can cause problems by blowing the droplets away from target and increase the chances of nontarget organisms being damaged. Usually, the best time to spray is in the morning when the temperature is low, the humidity is high, and the windspeed is fairly light.

Technology can also play a part in reducing spray drift. A relatively new product that has made its way to the forefront in recent years are electrostatic spray technology. Along with reducing spray drift, this type of application equipment can improve canopy penetration, increase the underleaf coverage, and decrease the total volume per acre applied.

History: Electrostatic spray technology was created in the early 1930's to improve spray deposition. By the 1940's, the automobile manufactures took advantage of this technology and created a more efficient method of painting cars and trucks. It was not until the early 1980's when spray systems were researched for the agricultural community. Preliminary tests were performed on cotton crops.

How it Works: Like charges repel and opposite charges attract. This is the basic principle on this new design. As the chemical mix leaves the nozzle, it is exposed to a negative charge. These charge droplets are then attracted to the positively charged leaf surface.

Illistration from http://www.maxcharge.com

The principle that opposite charges attract is Coulomb's Law and above is a diagram depicting what happens as the charged spray droplets encounter the positively charged leaf surface.

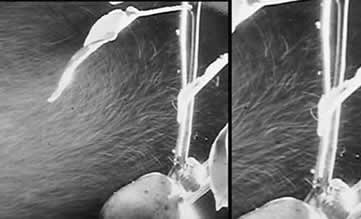

Photo from http://www.maxcharge.com

As you can see in the picture above, the charged spray droplets bend upward toward the underside of the leaf surface. Once the leaf has been adequately covered in spray material, the positive charge on the leaf dissipates allowing other droplets to find places in the canopy that have not been covered.

In Ali Bayat, Yusuf Zeren, and M. Rifat Ulusoy's article, "Spray Deposition with Conventional and Electrostatically-Charged Spraying in Citrus Trees", they stated the following. The authors found that electrostatically charged airblast sprayers had higher spray deposition on the undersides of the leaves while reducing the pesticide losses found on the ground under the canopy. They also found that the electrostatic sprayer offered higher biological efficiency in the control of citris white fly, Dialeurodes citri .

Sprayer Models:

Sprayer photos are from http://www.proaginc.com/

Vineyard:

Orchard:

Reference:

Bayat, Ali, Zeren, Yusuf, and Ulusoy, M. Rifat. "Spray Deposition with Conventional and Electrostatically-Charged Spraying in Citrus Trees." Agriculture Mechanization in Asia Africa and Latin America. 25 (1994): 35-39.